Laser Cut Architectural Metals

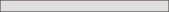

Laser cutting offers great design flexibility to create unique and iconic architectural surfaces.

Laser-cutting manufacturing enables the creation of custom hole designs on flat metal panels metal without the need for specialized tools, offering greater design freedom.

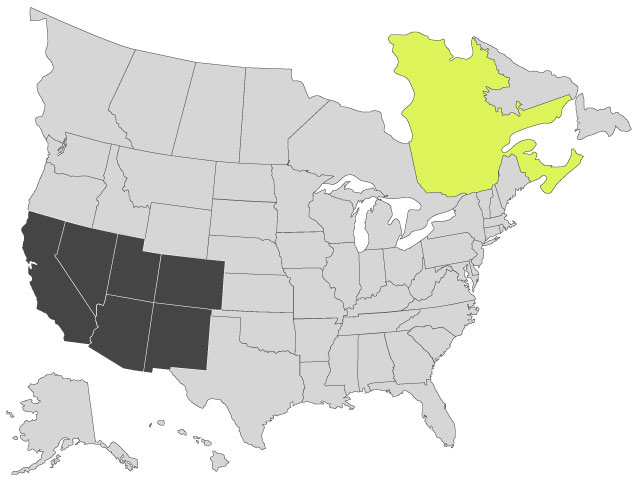

You can design your own panel pattern, use a standard pattern from AMICO (below), or work with AMICO to develop a custom pattern.

If you are designing your own panel, scale your design to meet your budget; patterns with more cuts will ultimately cost more because they take longer to cut. Planning a minimum opening of at least ¾” and the distance between should be at least 2x the thickness of the material.

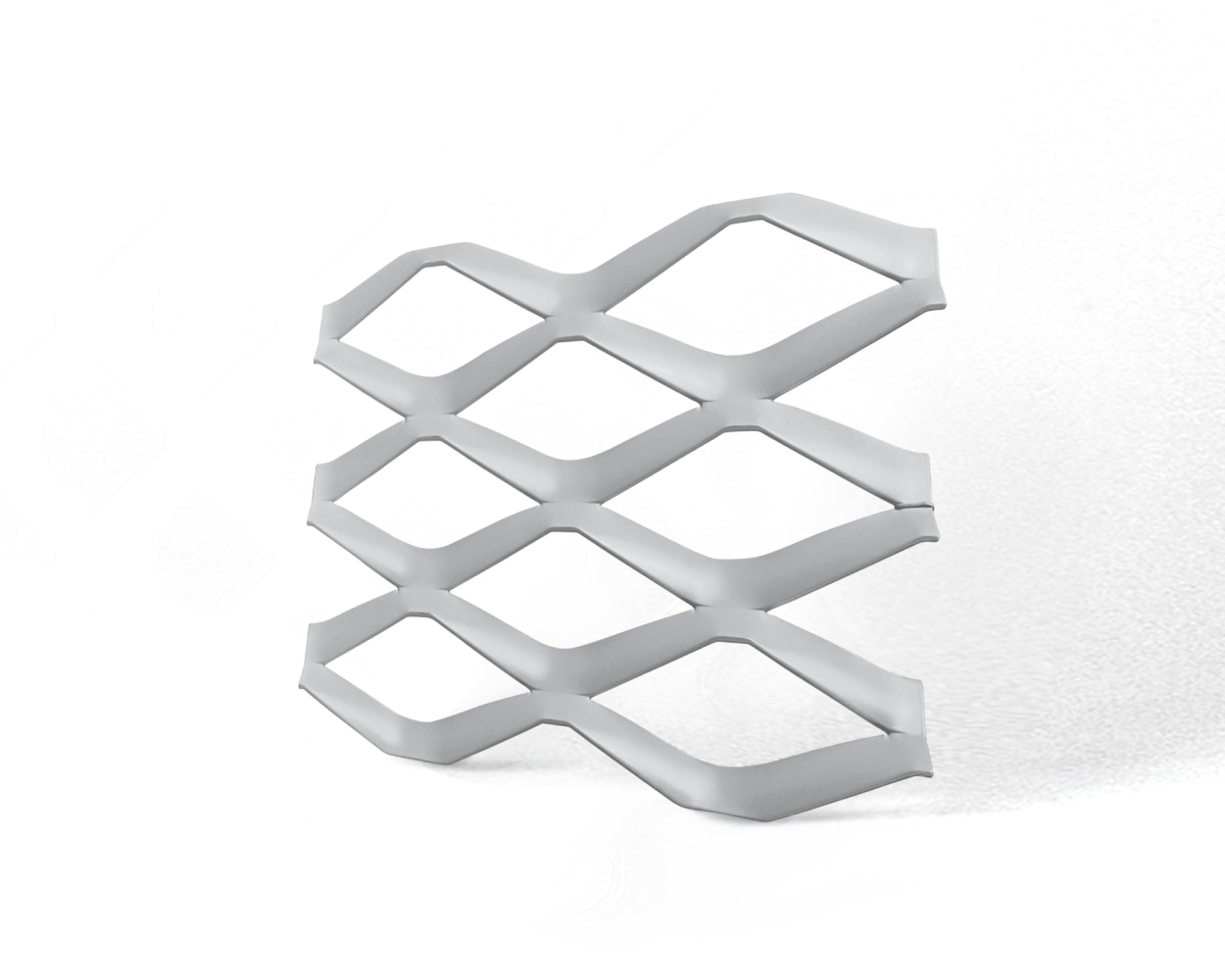

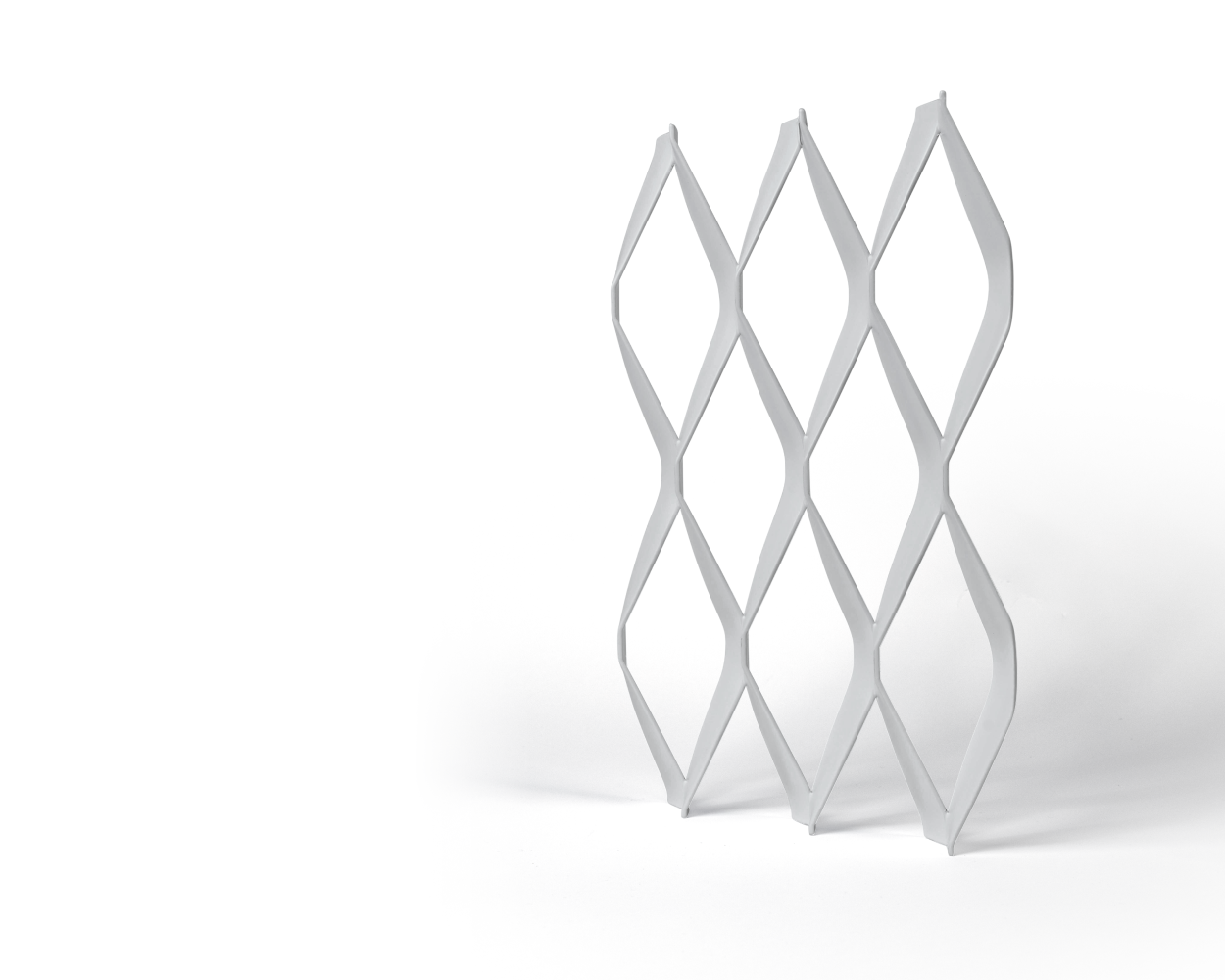

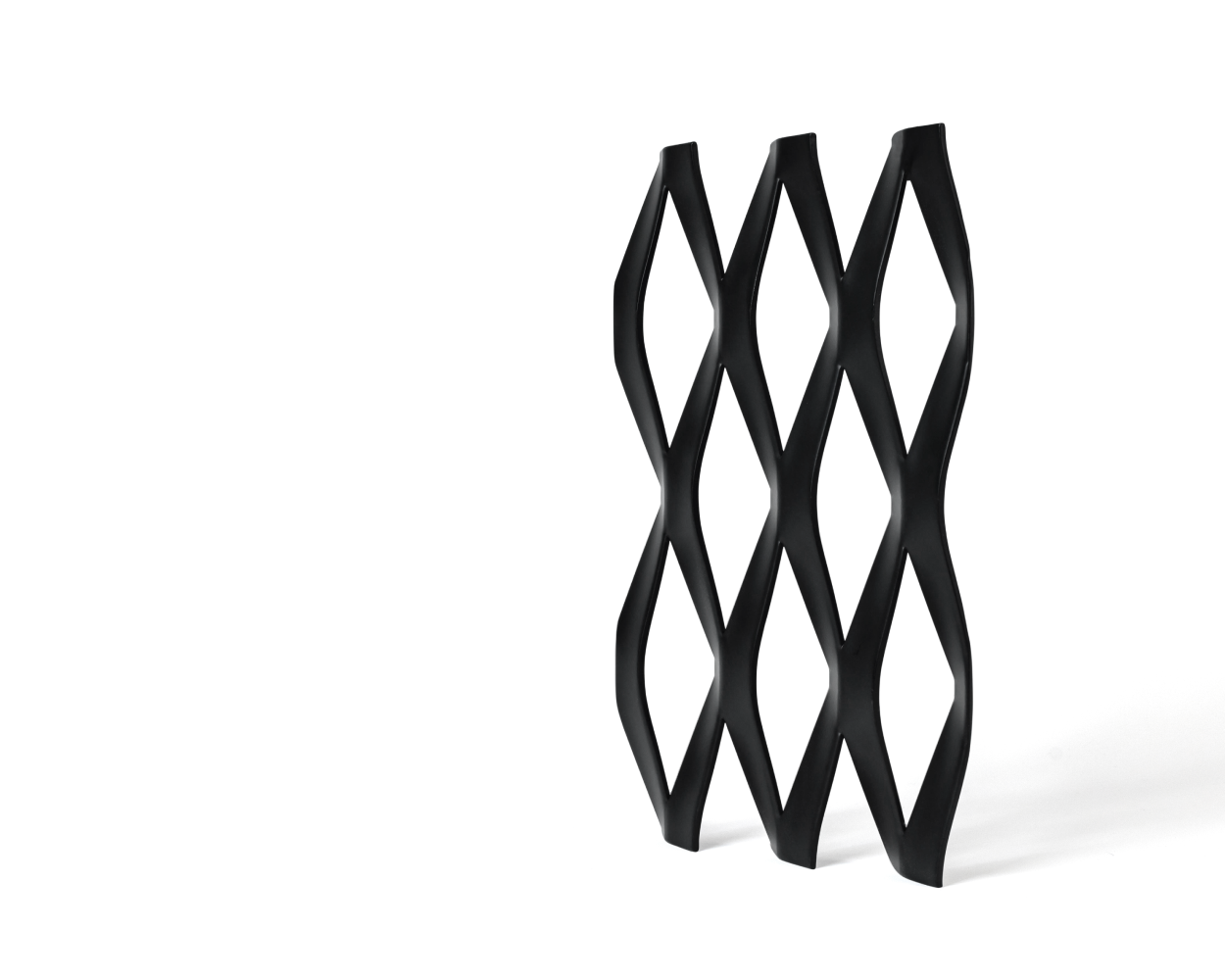

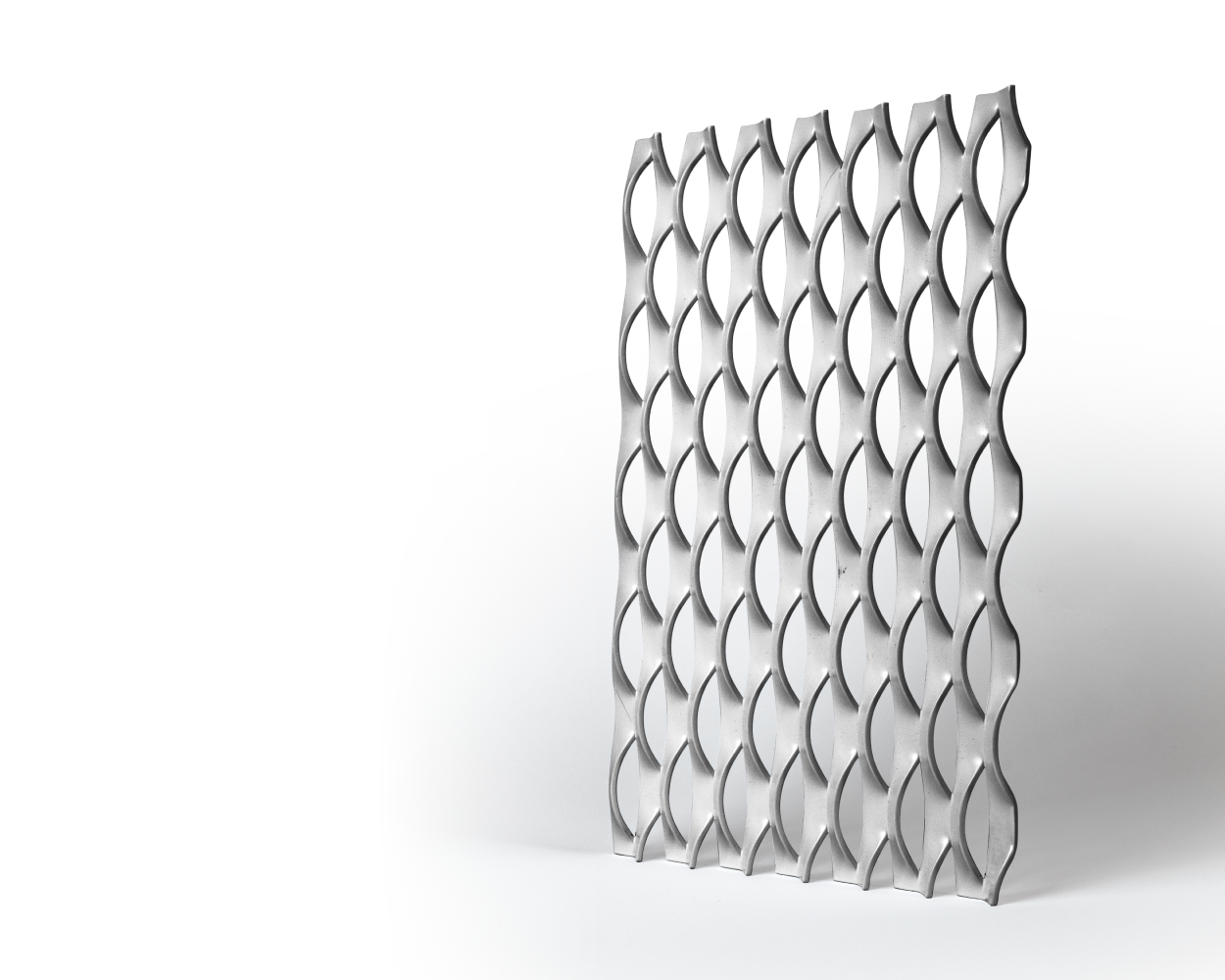

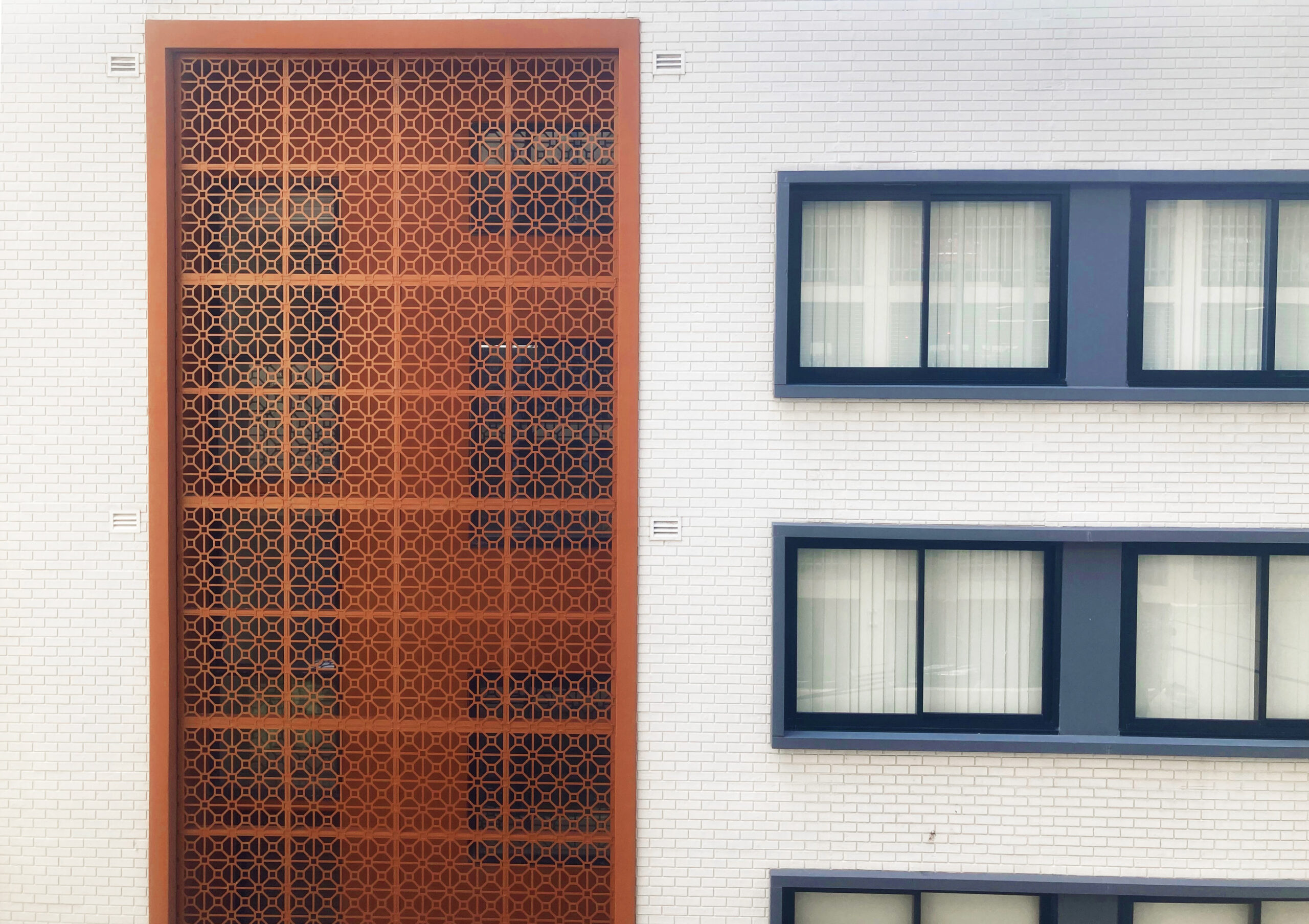

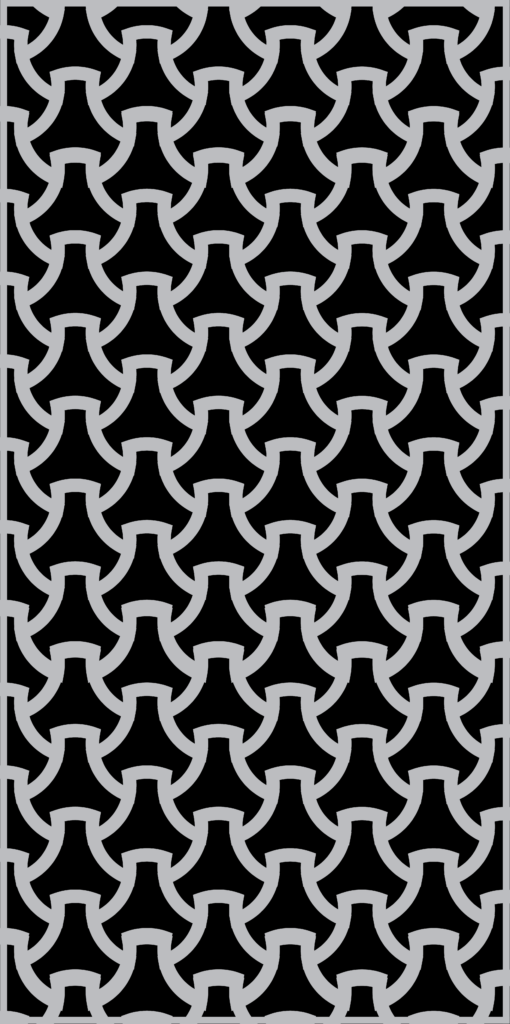

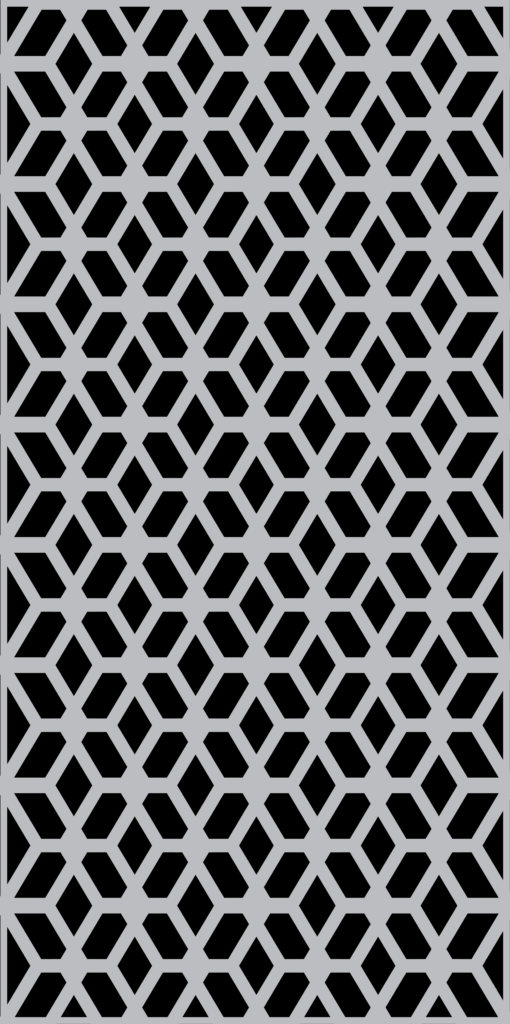

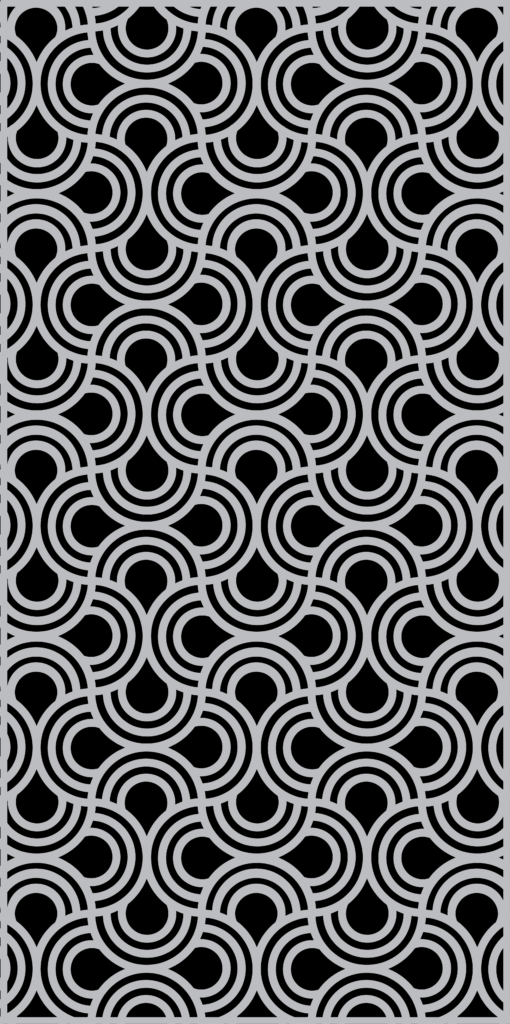

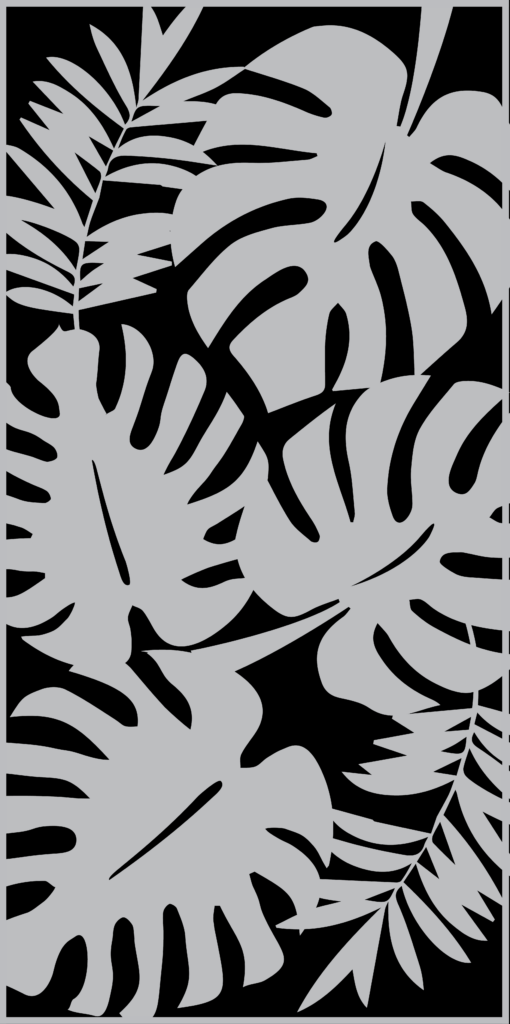

Pre-Designed Pattern Collections

Images are for reference; the exact scale and proportions depend on panel size and your design objectives.

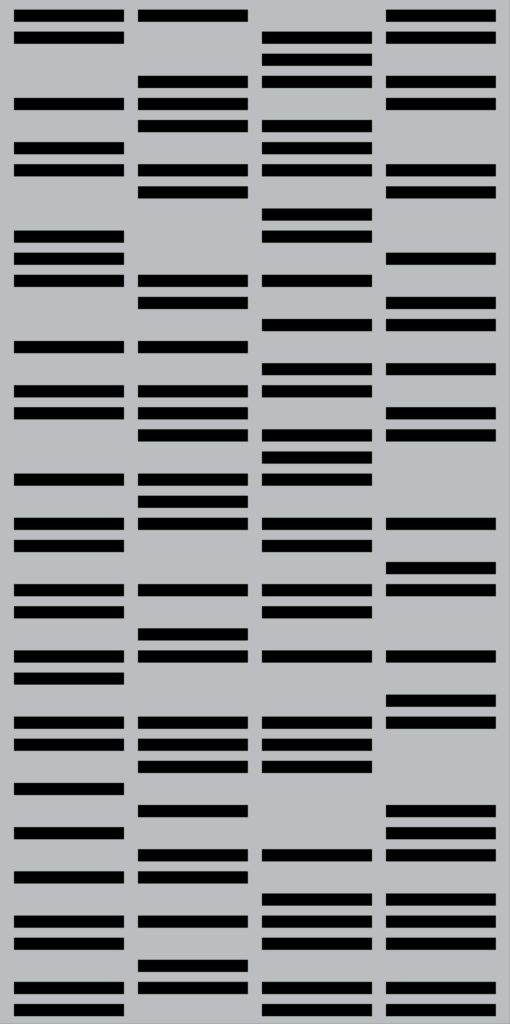

Moorish Collection

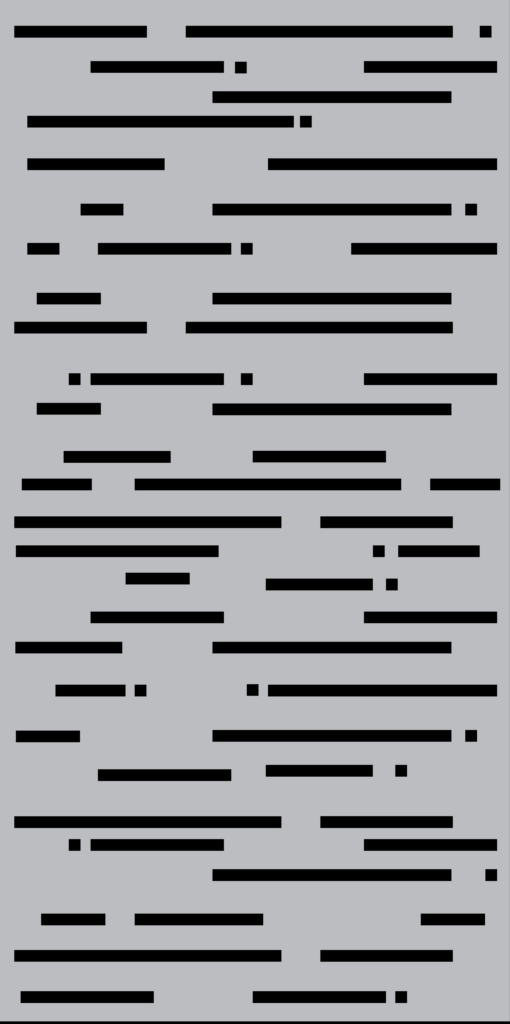

Geometric Collection

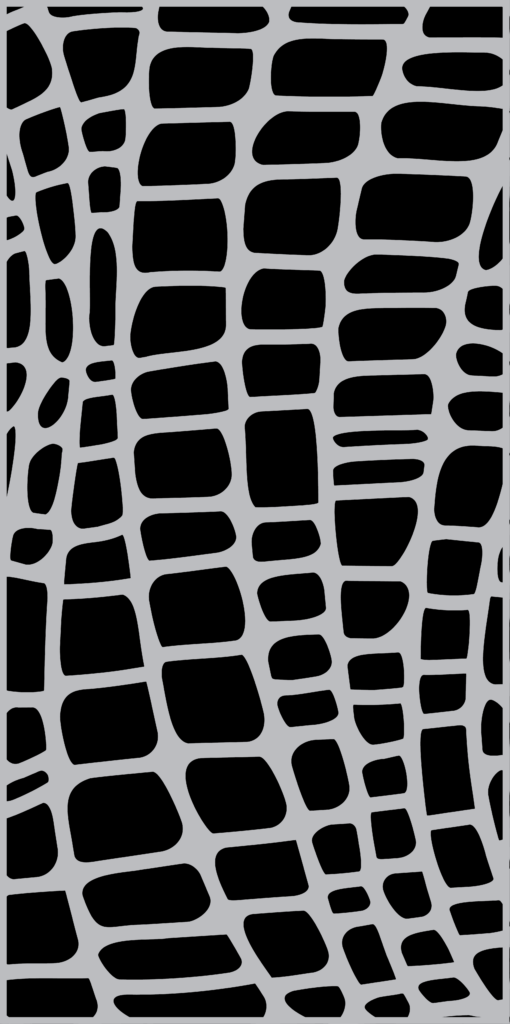

Organic Collection

Block Collection

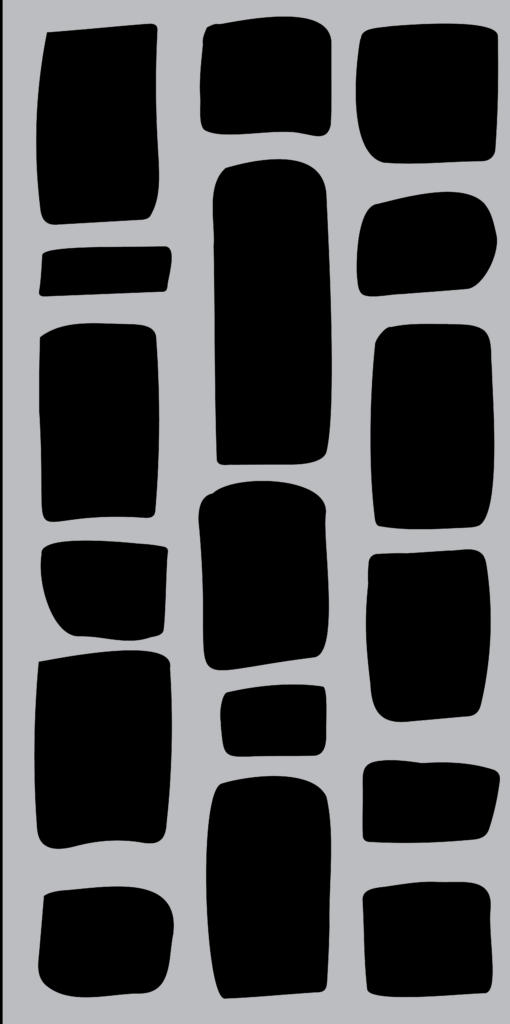

Large Shape Collection

Frequently Asked Questions

Can I get samples of a pattern?

Yes, contact your AMICO rep to discuss your exact needs. There will be a charge for the sample depending on it’s size and finish requirements.

Do you provide a complete installation system?

Yes, we work with our customers to deliver a finished product ready to install. AMICO will work with you to produce shop drawings and design a hanging approach.

What is the minimum order size?

You can order as little as one panel; however, you will not enjoy the economies of scale compared to larger orders.

Can stock patterns be customized?

Yes, all patterns are intended to be scaled and rotated to meet your needs. Scaling down a pattern may increase the cost.

How can I optimize the cost of my project?

- Stick to standard raw material sizes, 5’x12′, 5’x10′, or 4’x8′

- Plan panel sizes to minimize raw material waste

- If possible, use a panel that is the same size and pattern as much as possible.

- Time on the laser cutter increases costs, so reduced cut complexity is beneficial to your budget.