Sustainability

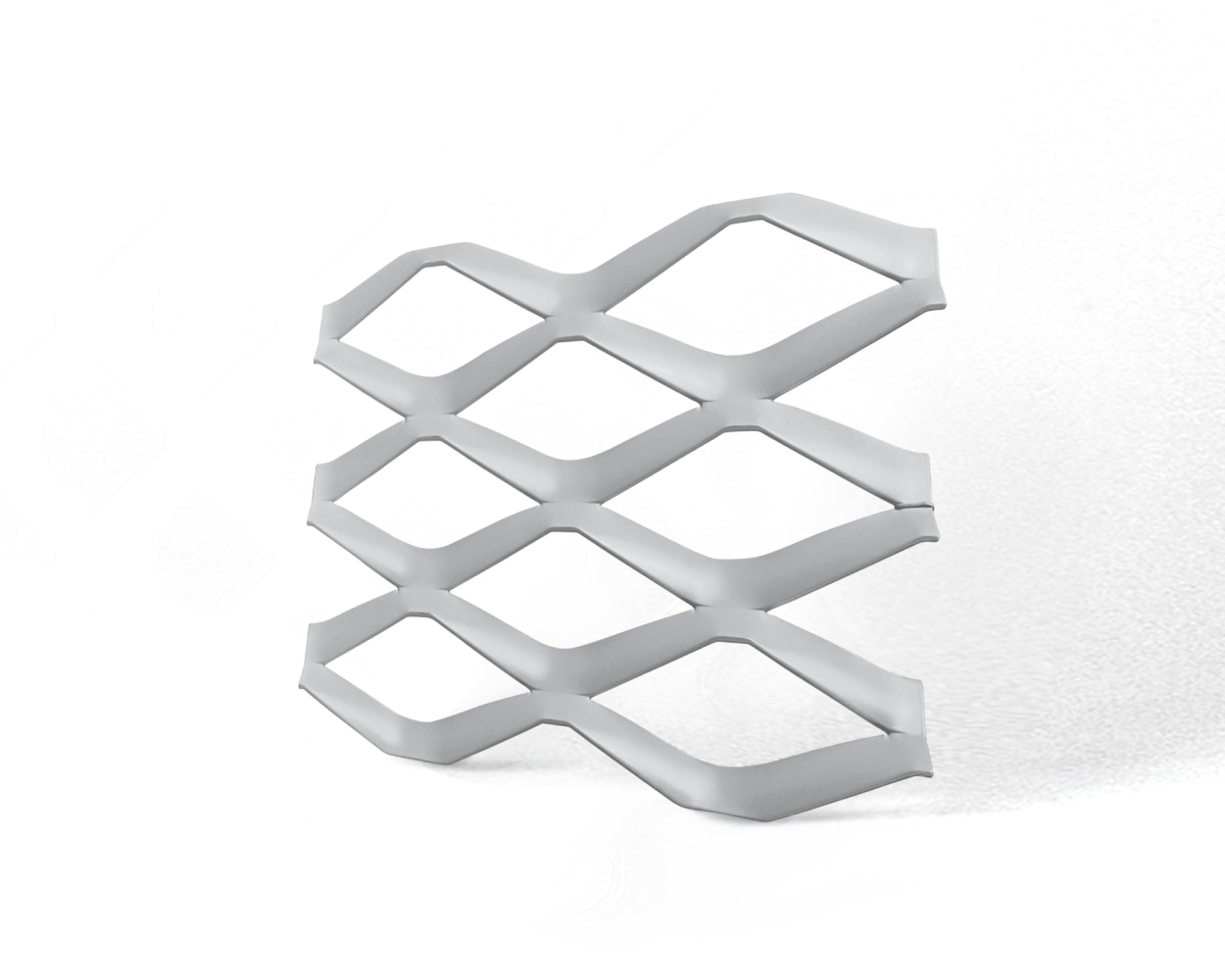

1 Prefabrication

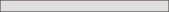

AMICO prefabricates our materials to arrive at the job site without further work outside the installation, eliminating costly on-site waste. Click here to see a typical prefabrication-installation process for expanded mesh.

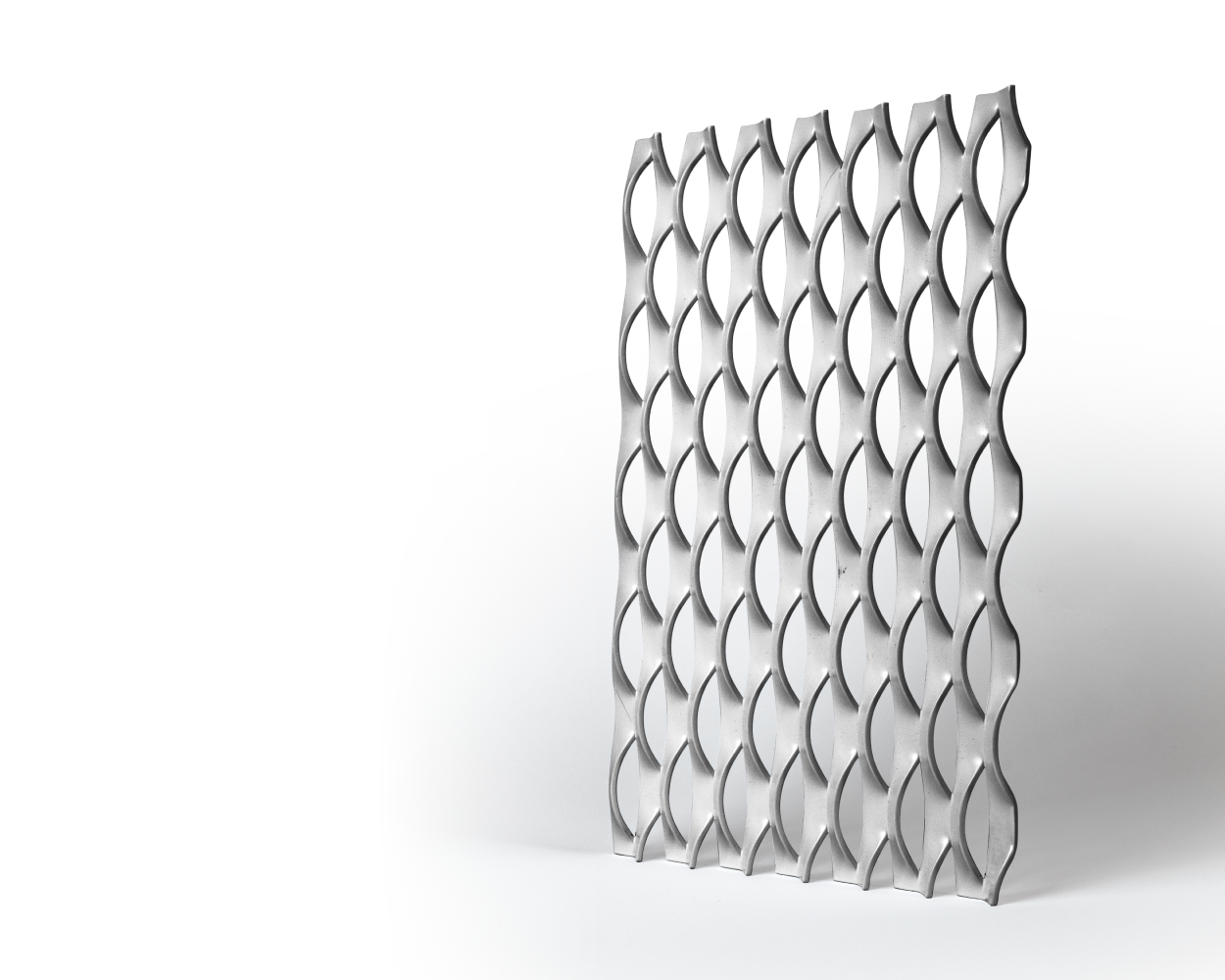

2 Recyclability

Aluminum, steel, and stainless steel are some of the most recycled materials in the building industry. AMICO products are attached to structures and assembled using mechanical fasteners, making them easy to remove, isolate, and segregate for 100% recyclability.

3 Product Longevity

The extreme durability of aluminum and stainless-steel products means their lifespan is longer than many other materials, leading to reduced maintenance and cost of ownership.

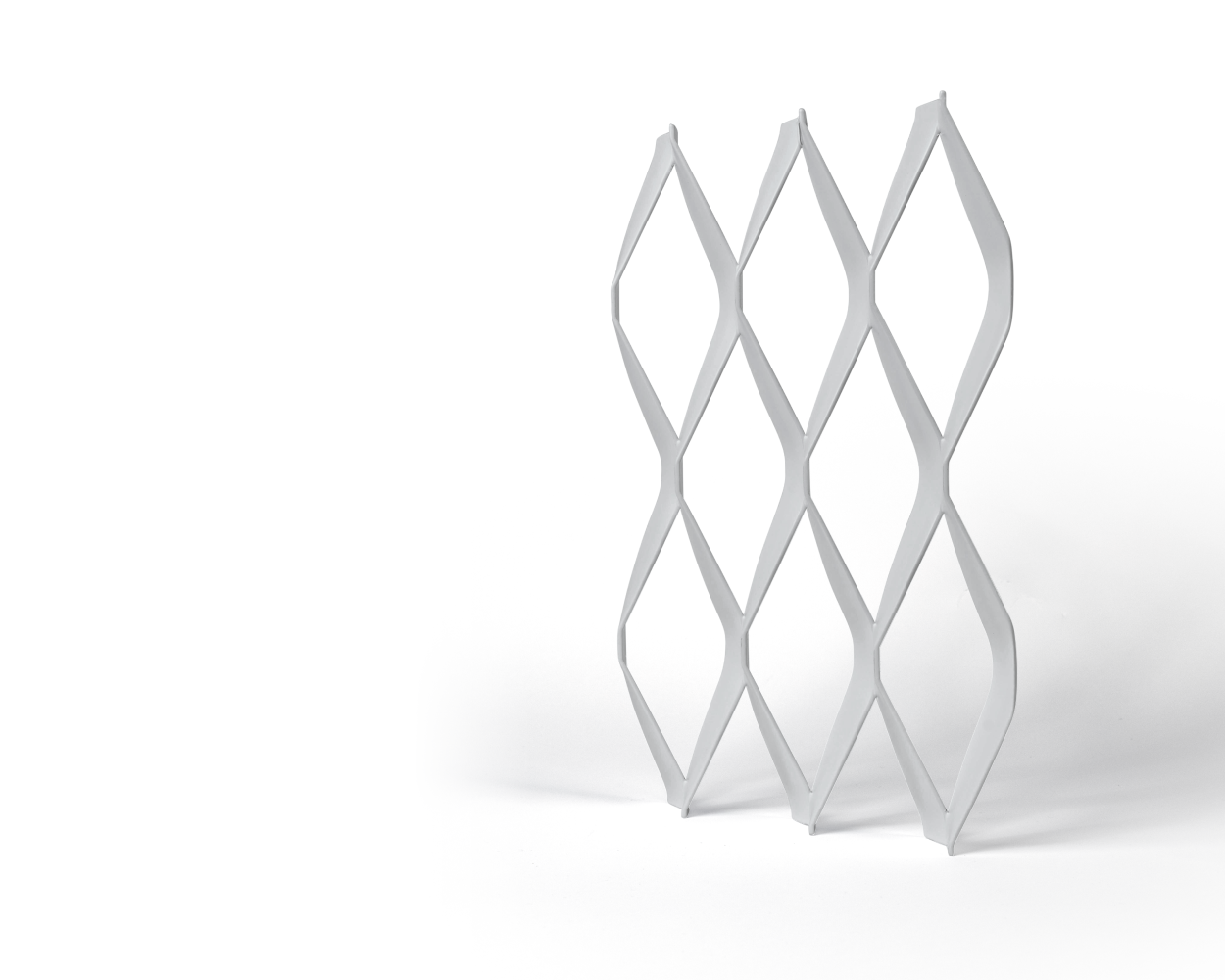

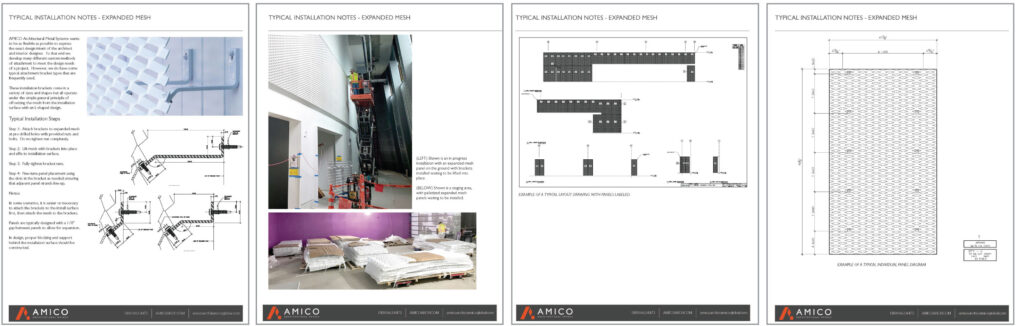

4 Reducing Heat Gain

AMICO’s materials are frequently applied as sunshades. These sunshades can reduce solar heat gain, thus reducing the energy load on a structure and eliminating carbon waste while improving the cost of ownership. Read our case study for more information.

5 Chemical Free Maintenance

Aluminum products are virtually maintenance-free, can be wiped clean with diluted soft soap and water, and do not need solvents, bleaches, or varnishes that harm the environment and water supply.

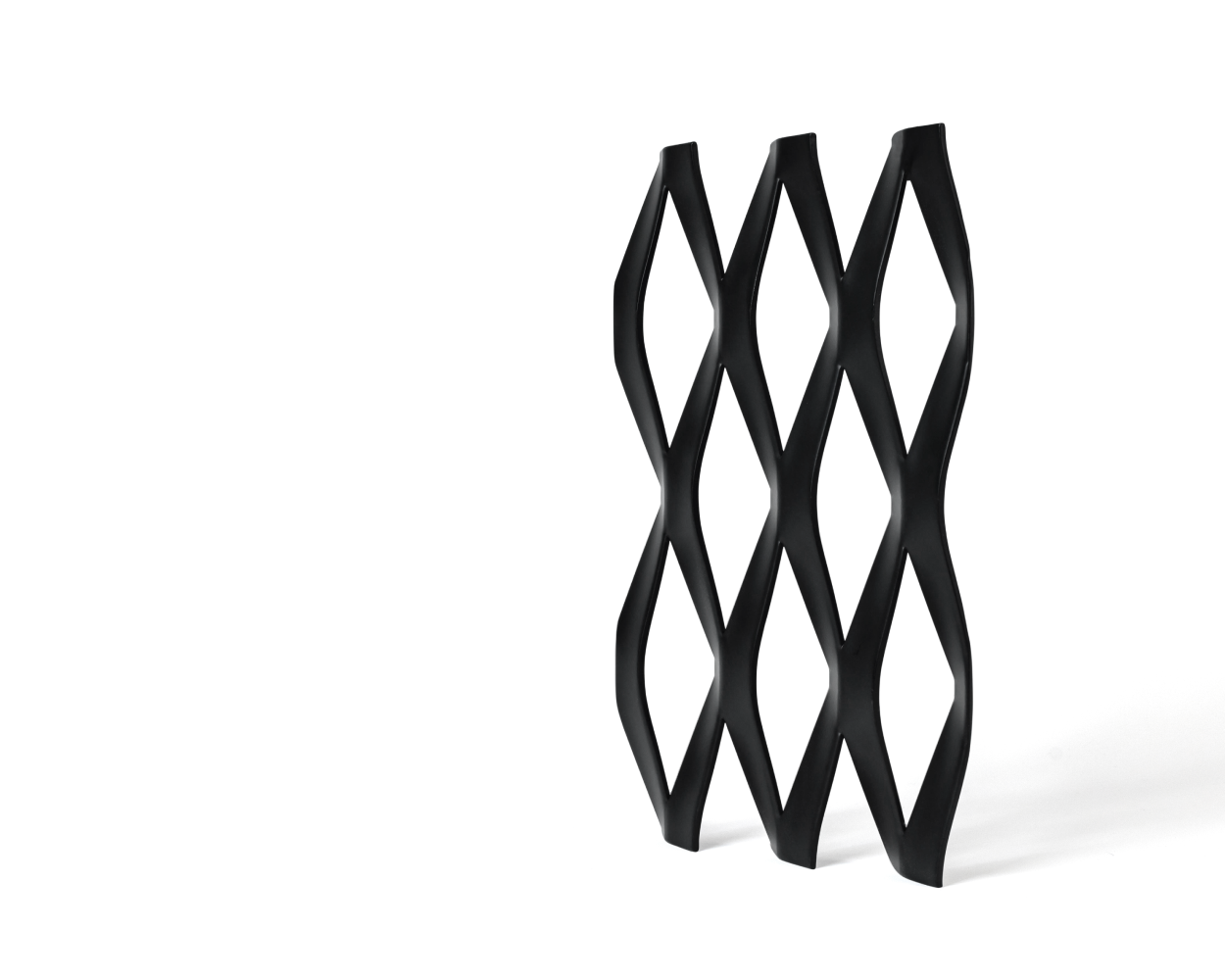

6 No VOC Powder Coating

Most powder coat finishes emit either low or no volatile organic compounds and do not impact the aluminums ability to be recycled.

7 LEED Environmental Categories and Credits

Based on AMICO’s project experience, our materials may contribute to the USGBC LEED rating in the following categories:

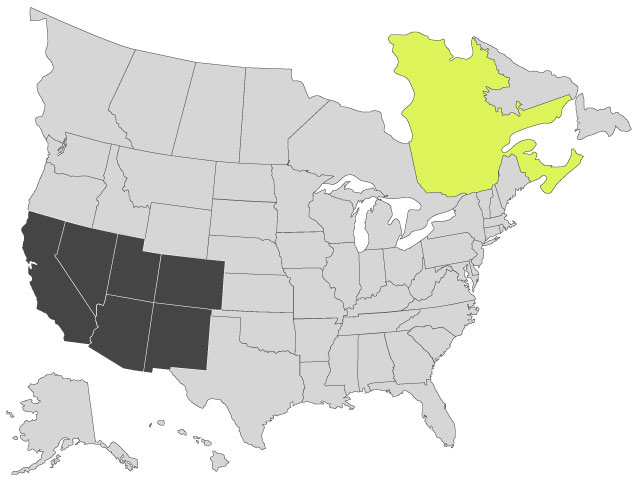

Material and Resource:

- MR Credit 4.1 and 4.2 for recycled content

- MR Credit 5.1 and 5.2 for regional materials

Indoor Environmental Quality

- EQ Credit 4.1 for Low-Emitting Materials

- EQ Credit 8.1 75-Percent Daylight and Views

- EQ Credit 8.2 90-Percent Daylight and Views

Innovation in Design Credit 1.1

Energy and Atmosphere

- EA Credit 1 Optimized Energy Performance